Shandong Fengtu IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

time:2025-04-09 09:29:32 source:Weather Station viewed:88 time

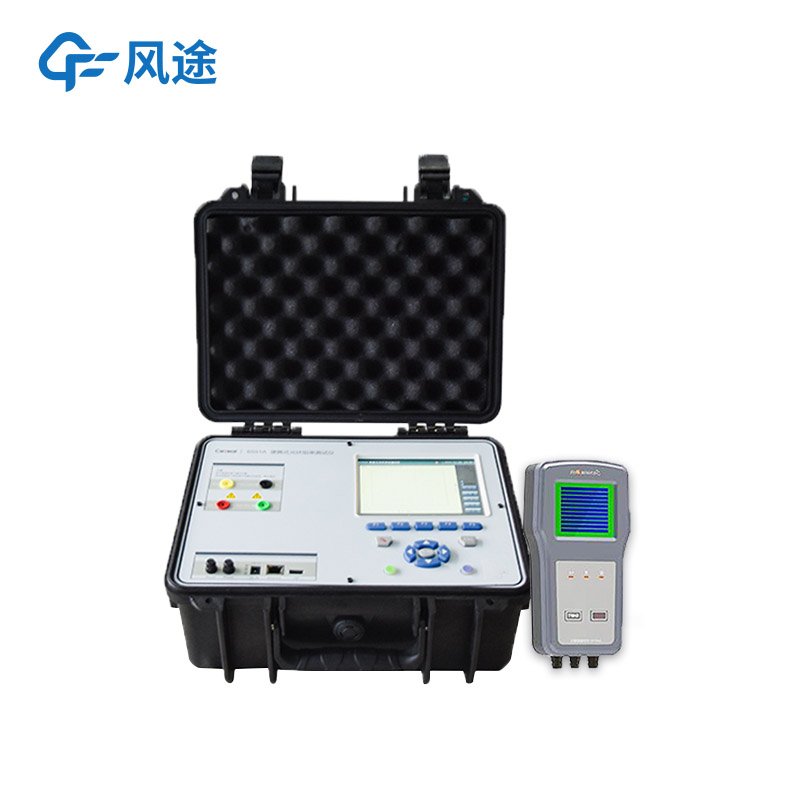

Throughout the entire process of photovoltaic (PV) modules from production to actual use, various links such as transportation, handling, and installation may cause damage to the modules. And this kind of damage may only become apparent after the modules are installed, which will lead to a lower power generation. If we wait until the power generation drops to find out the cause, it will not only increase the difficulty of troubleshooting but also may delay the solution to the problem. Therefore, I suggest conducting sampling tests before the installation of PV modules and carrying out a comprehensive inspection with a Portable IV Curve Tester on the PV array after the modules are installed and fixed to ensure that the performance of the modules meets the requirements.

According to relevant statistics, in PV power plants, the proportion of power plants whose power generation efficiency decreases due to the power generation performance problems of the modules is at least over 10%. As an efficient detection tool, the Portable IV Curve Tester can quickly and accurately detect the I-V characteristic curve of PV modules, helping to identify abnormal performance of the modules. Through detection and combined with data analysis, it is possible to effectively determine whether the quality of the PV array after installation is qualified.

The electrical performance failures of PV modules usually do not cause the power plant to stop generating electricity completely or trigger safety accidents, but they will significantly reduce the power generation efficiency. According to the specification requirements, when the power generation efficiency drops by more than 5%, the quality of the power plant is regarded as unqualified. Although the characteristic curve can intuitively reflect the problems of the modules, in order to conduct an in-depth analysis of the root causes of the problems, it is still necessary to carefully interpret the curve.

There are various reasons for the abnormal characteristic curve of PV modules. Common ones include dust shielding, breakage of individual solar cells, mismatch of module parameters, short circuit of bypass diodes, etc. By detecting the shape of the I-V characteristic curve of the PV array, the Portable IV Curve Tester can not only initially determine whether the power generation performance of the modules is normal but also accurately locate the faulty modules, so as to replace the faulty components in a timely manner and ensure that the power plant restores its normal power generation efficiency. This detection method is very necessary for the quality control and performance optimization of PV power plants.

In a wheat planting area in the North China Plain, Soil Moisture Testing Equipment is playing an important role.This area has set up multiple soil moisture monitoring points. Each monitoring point is equipped with advanced sensor equipment. These sensors can monitor soil moisture, temperature and ot...

Soil is the cornerstone of agriculture, providing crops with the water, nutrients, air and temperature they need to grow. Soil formation is influenced by a number of factors, such as original soil composition, climate, biological action, topography and time of year, as well as human farming activiti...

Ultrasonic wind speed sensor principle:It uses ultrasonic time difference method to realize wind speed and wind direction measurement. As the speed of sound propagation in the air, it will be and wind direction. Above the airflow speed iteration. If the ultrasonic propagation direction and the wind...

Real-time monitoring of soil moisture is crucial to agriculture, not only for the quality of crop growth, but also for agricultural drought mitigation. Modern soil moisture monitoring technology achieves precise control of soil moisture status through intelligent means, which greatly improves the sc...