Shandong Fengtu IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

time:2025-03-10 09:26:52 source:Weather Station viewed:110 time

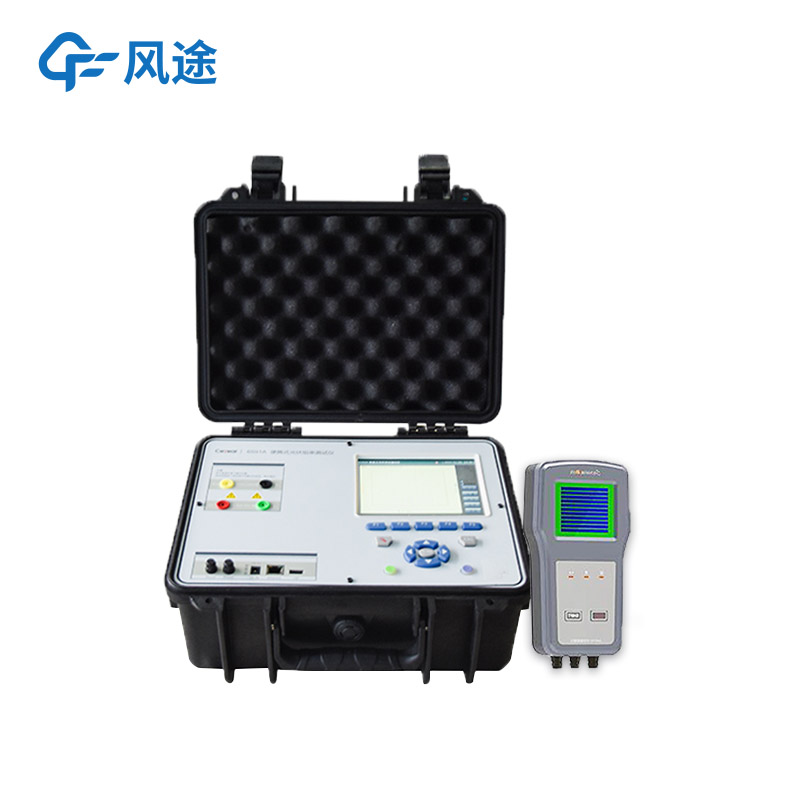

IV curve testing is a commonly used method for detecting the performance of photovoltaic power generation systems. The Portable IV Curve Tester can conduct on - site tests on the power, open - circuit voltage, short - circuit current of photovoltaic modules under different temperature and irradiance conditions, as well as the voltage and current at the maximum power point, and convert the obtained data to standard test conditions (STC). With the help of a special algorithm, this tester can also calculate the series resistance Rs, which is helpful for troubleshooting problems in the modules and their connections.

Conducting IV characteristic tests on photovoltaic modules can accurately verify the power generation efficiency of the equipment and the stability of the system. To further improve the operation efficiency of the power station, it is necessary for the power station to regularly organize spot - checks of the IV characteristic tests of the modules.

Operation and maintenance personnel select photovoltaic modules from different areas and different installation batches in the station as inspection samples. During the noon period when there is abundant sunlight and stable irradiance, the Portable IV Curve Tester is used for testing. Simulating the real working scenario, operation and maintenance personnel carefully record the current and voltage values of each module when the irradiance reaches 1000W/m², and analyze the operation status of the modules based on the IV curve generated by the equipment.

During the entire spot - check process, operation and maintenance personnel not only pay attention to whether the power attenuation degree of the modules is within the specified range but also deeply analyze key parameters such as the fill factor, open - circuit voltage, and short - circuit current to comprehensively evaluate the performance of the modules. Once a module with performance deviation or potential failure is found, operation and maintenance personnel immediately mark it and include it in the subsequent repair and replacement plan of the power station to fully ensure that the overall power generation efficiency of the power station is not affected.

The spot - check action of the power station is not only a comprehensive "physical examination" of the performance of photovoltaic modules but also a key measure to continuously optimize the operation and maintenance strategy and improve the power generation efficiency.

what is meteorological station A monitoring system built to acquire meteorological data, integrating multiple sensors, and can be used on land or at sea....

A UAV-specific visibility meter is a device specifically designed to measure and monitor visibility in the atmosphere, with the aim of providing accurate visibility information to assist UAV operators in flight decision-making and flight safety management. Visibility is the distance at which the hum...

Highway meteorological services are very important, and the factors affecting traffic safety are not only man-made, but also weather-related. Therefore, it is very necessary to strengthen the weather observation on the highway, especially in the case of bad weather, pay special attention to the chan...

Monitoring soil moisture is very important. Firstly, it can accurately understand the moisture content in the soil, provide scientific basis for agricultural production, ensure that crops grow in a suitable moisture environment, and improve yield and quality. Secondly, it can reasonably arrange irri...