Shandong Fengtu IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

time:2025-03-31 09:30:56 source:Weather Station viewed:76 time

Large-scale ground photovoltaic power stations are characterized by their huge scale, vast land occupation, and heavy inspection tasks. Some ground power stations also face the challenge of complex geographical environments, such as floating solar power stations on water surfaces and mountainous power stations. These power stations have complex and rugged terrains, inconvenient transportation, and scattered arrays. In such large power stations, there are a large number of components. Each solar panel and connection point may have faults, and component failures are one of the main reasons for the gradual decline in photovoltaic power generation.

In the photovoltaic area, there are various risks, including loose or disconnected connectors, unreasonable cable laying, decreased insulation performance, grounding faults, component mismatch, and component shading. These problems impose a heavy burden on the operation and maintenance work. In the traditional operation and maintenance mode, only after an alarm signal appears can the operation and maintenance personnel conduct offline and on-site inspections by carrying equipment, and rely on manual work to output reports and propose solutions. This method is time-consuming and labor-intensive, and the results vary greatly. Moreover, operation and maintenance personnel can only receive information and deal with problems when the faults have already occurred or the components have been damaged. If problems can be detected and solved in the early stage of component failures, it can not only reduce the workload of operation and maintenance but also lower the component damage rate, save operation and maintenance costs, and increase the revenue of the power station.

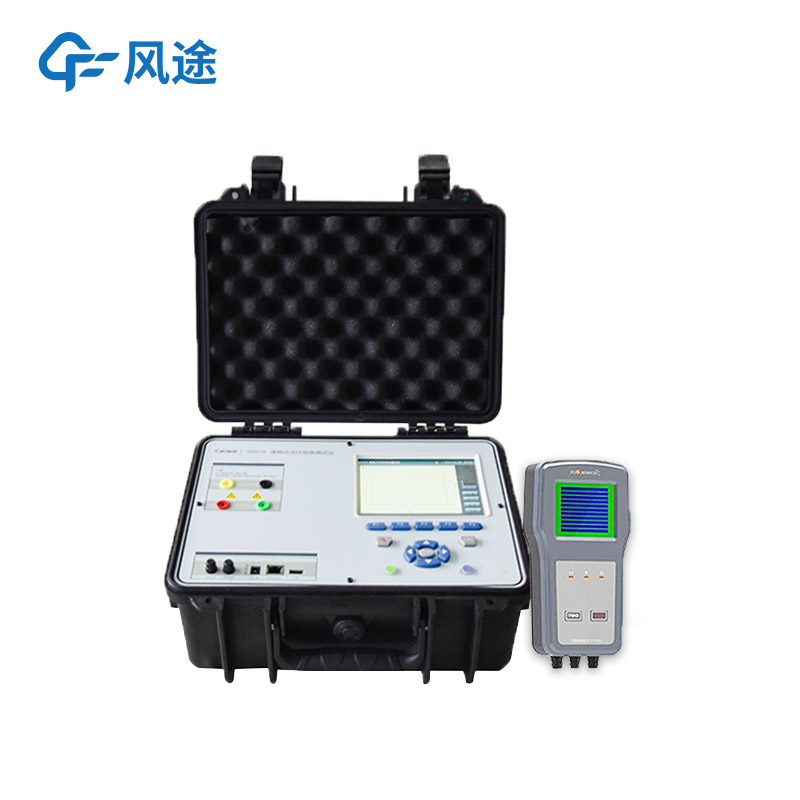

The emergence of the Portable IV Curve Tester has changed the traditional sampling inspection method. It can conduct 100% inspection and diagnosis of photovoltaic components and automatically generate reports. It can accurately detect up to about 30 types of faults. The entire inspection process is carried out remotely without the need for on-site manual inspection. Compared with the traditional method, the Portable IV Curve Tester can detect more problems, and even solve potential problems in advance, reducing the component failure rate and ensuring the healthy operation of the power station.

wind meter application agriculture provides important wind speed and direction data that can help ranchers and farmers make critical management decisions in agricultural production....

With the popularization of transportation, vehicle safety has gradually become a focus of social concern. Low visibility is one of the main causes of road traffic accidents. In order to improve driving safety, vehicle-mounted mobile visibility meters have come into being. In this article, we will el...

Fengtu specializes in the research, development, and production of environmental online monitoring equipment. Its FT-WQX2 Ultrasonic Wind Speed Direction Sensor has been recognized by the market in the field of meteorological monitoring.This device is capable of continuously monitoring outdoor meteo...

agricultural sensors are used to detect information about the growing environment of agricultural crops, such as air temperature and humidity, light intensity, carbon dioxide and other data required for field cultivation....