Shandong Fengtu IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Model:FT-S9

Brand:fengtu

one.Online turbidity sensor working principle

Online turbidity sensor for online turbidity measurement is an online analytical instrument for continuous measurement of suspended particle concentration.Online turbidity sensor determines the concentration of particles in a liquid by measuring the scattering of light.It uses a light source to shine into a liquid and then measures the scattered light intensity at different angles.This sensor uses the 90° angle scattered light method to linearly process the collected values, and outputs turbidity values through a temperature compensation algorithm.

two.Online turbidity sensor technical parameters

| Measurement principle | scattered light method |

| Measuring range | Default 0~3000NTU, 0~40NTU 0~1000NTU can be customized |

| resolution | 0.1NTU |

| Accuracy | ±1%, ±0.3℃ |

| temperature compensation | Automatic temperature compensation |

| Output mode | RS-485 (Modbus/RTU) |

| Storage temperature | -5-+65℃ |

| working environment | 0~50℃,≤0.2MPa |

| Installation method | Submersible installation, 3/4NPT mounting thread |

| Cable length | 5m |

| Power consumption | 0.2W,12V power supply |

| powered by | DC: 12V-24V |

| Protection level | IP68 |

| Calibration method | Two point calibration |

| Shell material | ABS |

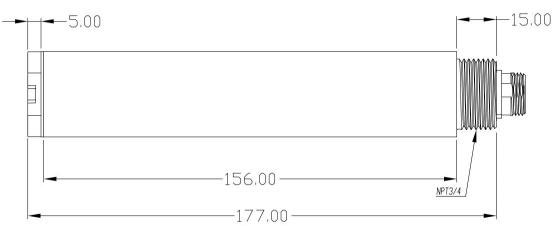

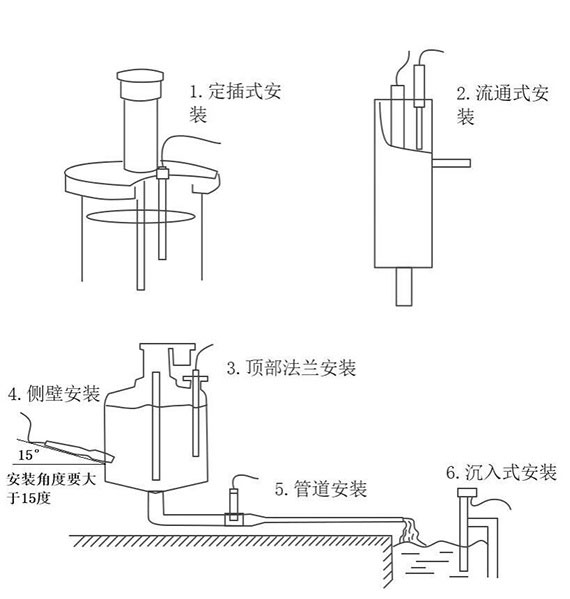

three.Online turbidity sensor size/installation

1.Online turbidity sensor size chart

2.Wiring diagram

The cable is a 5-core shielded wire:

Red wire - power cord, black wire - ground wire, green wire - 485A, white wire - 485B

3.Online turbidity sensor installation

Note: The sensor cannot be installed upside down or horizontally, and must be installed at an angle of at least 15 degrees.The test port will not touch the container wall within 5CM to the left and right, and 10CM below

Four.Online turbidity sensor maintenance and care

Sensor maintenance:

If the sensor needs to be cleaned, use warm water and an appropriate amount of detergent to clean it.

Notice:

Avoid strong vibrations that may damage the transparent glass in front of the ring, and do not scratch it with hard objects.

five.Online turbidity sensor user calibration

The sensor has been rigorously calibrated when it leaves the factory, and generally does not require user calibration.If user calibration is performed, you can execute the factory reset command if you want to restore it.

5.1 Zero point calibration

Put the sensor into a non-transparent container.Use distilled or purified water for the solution.Make sure that the sensor's test port does not touch the container wall within 5CM to the left and 10CM below.After the value stabilizes for 30 seconds, perform zero point calibration according to the communication instructions..

5.2 Slope calibration

Put the sensor into a non-transparent container.Use a solution with known turbidity (the turbidity value should be greater than 20% of the range).Ensure that the sensor’s test port does not touch the container wall within 5CM to the left and 10CM below.Wait for 30 After the second value is stable, perform slope calibration according to the communication instructions.

Multifunctional automatic weather stations add various functions to the previous weather observation equipment, such as wind speed and wind direction sensors, rain barrels, etc. All these instruments have their own different uses and can be used to measure various meteorological elements and can per...

What is the use of a regional automatic weather station? It is an important means of weather observation, a new product based on modern sensor network technology, which collects weather information such as temperature, humidity, wind speed, wind direction, precipitation and barometric pressure at a...

industrial sensors Measuring the physical characteristics or changes in the industrial environment, types are: temperature sensors, pressure sensors, level sensors, infrared sensors, smoke sensors, optical sensors, etc....

In the operation and maintenance of expressways, slope disaster monitoring has always been a key aspect. Traditional monitoring methods, limited by high equipment costs, often focus only on key slopes, leaving many potential disaster-prone locations outside the monitoring scope. The sudden nature of...